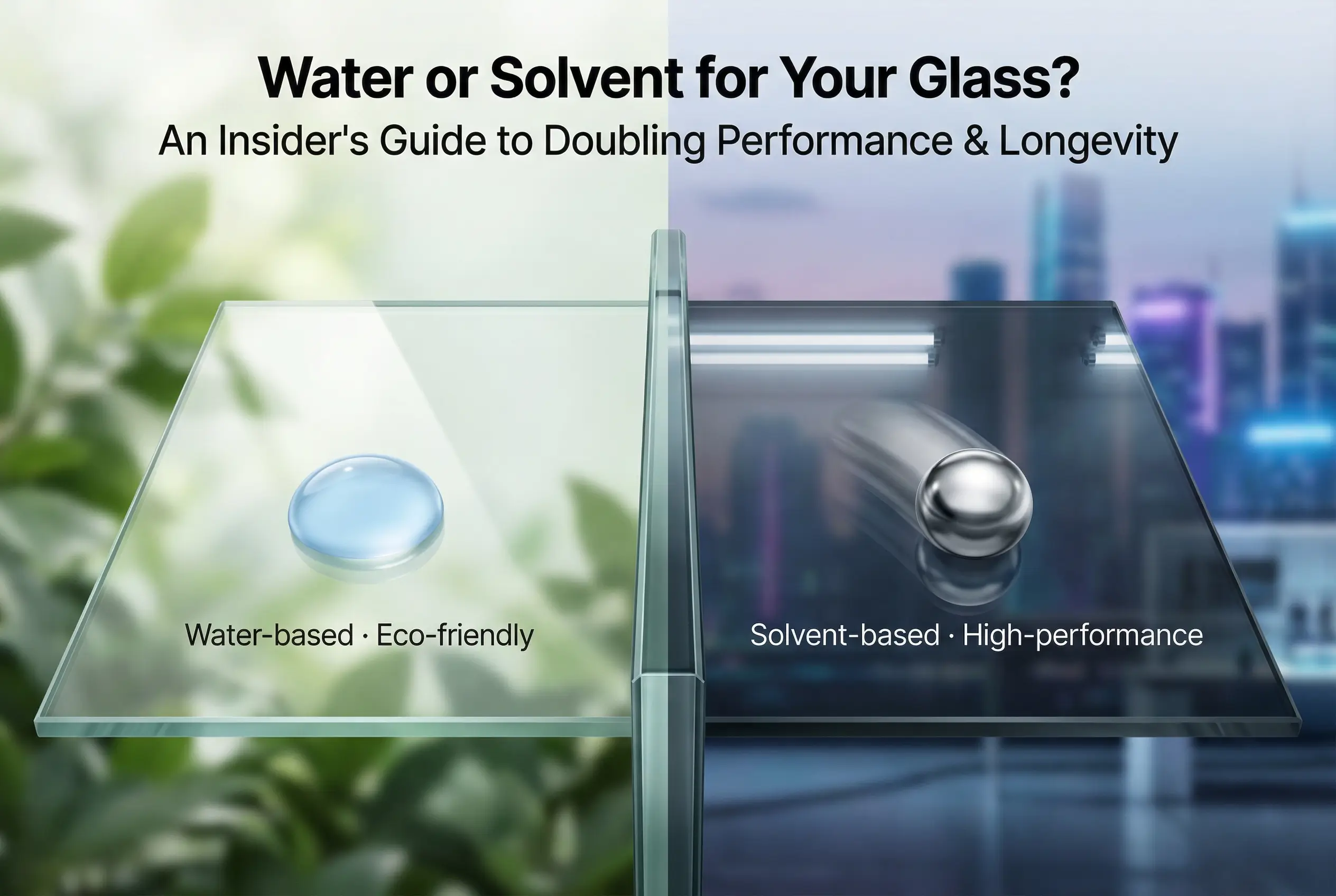

When it comes to enhancing the functionality and durability of glass surfaces in automotive, architectural, and residential applications, hydrophobic nanocoatings have become a critical solution. The two most common types on the market are Water-Based Hydrophobic Nanocoatings and Solvent-Based Hydrophobic Nanocoatings. What are the key differences? Which one is right for your project? As a seasoned product operator, I’ll break it down clearly for you.

The Core Differences at a Glance

Before diving deep, let’s summarize the key distinctions in one table to give you a quick overview:

| Feature | Water-Based Glass Hydrophobic Nanocoating | Solvent-Based Glass Hydrophobic Nanocoating |

|---|---|---|

| Core Formulation | Water-based carrier, uses water as the dispersion medium. | Solvent-based carrier, typically contains organic solvents. |

| Curing Process | Air drying + cross-linking reaction (water evaporation). | Solvent evaporation + cross-linking/curing. |

| Typical Odor | Low to no odor. | Noticeable solvent smell during application. |

| Eco-Friendliness & Safety | High. Low VOC, safe application, minimal health impact. | Medium. Requires good ventilation and protective gear. |

| Ease of Application | High. Good leveling, forgiving, beginner-friendly. | Medium. Fast drying; requires skill to avoid streaks. |

| Adhesion / Durability | Excellent (after full cure), strong weather resistance. | Exceptional. Superior adhesion and chemical resistance. |

| Hydrophobic Effect | Excellent, water contact angle often >110°. | Outstanding, water contact angle often >120°, pronounced lotus effect. |

| Suitable Substrates | All glass types; requires immaculately clean surface. | All glass types; slightly more tolerant of minor surface residue. |

| Typical Cure Time | Quick touch-dry; full cure may take several hours to 24h. | Fast touch-dry; full cure is generally quicker. |

| Clean-up | Tools easily cleaned with water. | Tools require specific solvents for cleaning. |

Deep Dive: Characteristics & Strengths of Each Product

1. Water-Based Glass Hydrophobic Nanocoating — The Eco-Friendly & Safe Choice

Characteristics:

Formulated with a water dispersion medium, it forms a dense, cross-linked network on the glass surface using nano-siloxanes and other active ingredients. Its hydrophobicity comes from the low surface energy layer formed after curing.

Key Advantages:

Green & Sustainable: Very low VOC content, complies with strict environmental regulations, safe for applicators and the planet.

User-Friendly Application: Minimal to no odor, suitable for confined or sensitive spaces (indoors, inside vehicles). Excellent leveling properties reduce the risk of application marks.

Safe & Convenient: Non-flammable, safer for storage and transport. Tools are cleaned easily with water.

Long-Lasting Performance: Once cured, it forms strong chemical bonds, offering excellent UV resistance, rain sheeting, and durability (typically 1-2+ years).

Ideal For:

Automotive Glass: Daily care and enhancement for windshields and side windows.

Architectural Window Glass: Perfect for occupied homes, offices, schools, and any space where indoor air quality is a priority.

Residential Glass (shower doors, partitions, mirrors): The safe, low-odor choice for household use.

Commercial projects with strict environmental and safety requirements.

2. Solvent-Based Glass Hydrophobic Nanocoating — The Ultimate Performance & Durability Choice

Characteristics:

Uses organic solvents as carriers to dissolve a high concentration of active ingredients. Solvents effectively penetrate and clean the micro-surface, enabling a robust bond between the nano-active material and the glass substrate.

Key Advantages:

Superior Adhesion & Longevity: Strong solvent penetration often leads to unmatched adhesion, with exceptional resistance to chemical corrosion and physical abrasion. Offers extended service life (premium products last 2-3+ years).

Top-Tier Hydrophobicity: Achieves higher water contact angles. Water beads are more spherical and roll off faster, providing a visibly stunning water-shedding, anti-contamination, and self-cleaning effect.

Harsh Environment Performance: Stable performance in areas with significant temperature swings or complex conditions. Slightly more forgiving on imperfectly cleaned surfaces.

Fast Curing: Solvents evaporate quickly, leading to rapid touch-dry and initial cure times.

Ideal For:

Premium Automotive Glass Care & Detailing: For those seeking the ultimate, longest-lasting hydrophobic effect.

Special Vehicle Glass (truck windshields, heavy machinery).

Exterior Architectural Glass in Severe Environments (high-rise curtain walls, regions with heavy rain/dust).

Industrial Glass & Specialized Glass Products.

Projects handled by professional applicators who can ensure proper ventilation and expert application.

How to Choose? Your Clear Decision Guide

Choosing between these products isn’t about "good vs. bad," but rather "which is the best fit for your specific needs."

Prioritize the 【Water-Based Nanocoating】 if:

You are a DIY user or your applicators are less experienced.

The application environment has limited ventilation or is sensitive to odors (homes, car interiors, offices).

Environmental impact and safety are your top concerns.

It’s for routine maintenance and you desire excellent, well-rounded performance.

Prioritize the 【Solvent-Based Nanocoating】 if:

You demand the "most extreme and longest-lasting" hydrophobic performance.

Application is handled by professionals with proper ventilation and PPE.

The glass faces harsh conditions (acid rain, sand, high-speed wind/rain).

The substrate may not be laboratory-level clean.

The Universal Golden Rule:

Regardless of your choice, a thorough, deep cleaning of the glass surface before application is the single most critical factor determining final results and longevity. Without cleanliness, there is no adhesion.

Summary

The Water-Based Nanocoating is the versatile, eco-friendly, and safe all-rounder, representing the industry’s green future.

The Solvent-Based Nanocoating is the high-performance, durable, and extreme specialist, excelling in demanding conditions.

We hope this analysis helps you cut through the confusion and make the smartest, most suitable choice based on your actual scenario, application conditions, and performance goals. Let every pane of glass have a clear, clean, and durable protective layer.

Have more questions about your specific application? Feel free to reach out anytime.