Builders now use next-generation cooling coatings to save energy. These coatings help the environment and follow strict rules. Europe has tough energy standards like the Energy Performance of Buildings Directive. The European Green Deal also pushes for better coatings. Countries want to make cities cooler. They use laws to help with this goal. Public money and research grants help new ideas grow faster. No-electric cooling coatings are a big change. They lower surface temperatures without using more power. This is changing how buildings are made in the future.

Key Takeaways

- Next-generation cooling coatings help buildings stay cool. They reflect sunlight and push heat away. They do not need electricity to work. These coatings help save energy and lower cooling bills. They also help buildings follow tough environmental rules and green standards. Cooling coatings last for many years. They can handle bad weather and chemicals. They do not need many repairs, so they are a good choice. Cooling coatings can be used on roofs, walls, roads, and machines. They help make places more comfortable and safe. New technology and more people wanting them make these coatings important. They help save energy and fight climate change.

Cooling Coating Technology

What It Is

Next-generation cooling coatings are a big step in building technology. These coatings do more than just protect surfaces. They help control heat. The 3U No-Electric Cooling Coating is a great example. It uses special nanomaterials and strong polymers. These materials reflect sunlight and let heat out. Builders use these coatings to keep things cooler. They also help save energy and make buildings last longer.

Modern cooling coatings are not like old thermal barrier coatings:

-

They do more than just block heat. They reflect sunlight and send heat away.

-

Old coatings did not last long in tough places. New coatings are stronger and resist chemicals better.

-

These coatings stop damage from hot and cold, chemicals, and bad weather. This makes them good for hard jobs.

Next-generation cooling coatings are not just for protection. They help save energy, keep people safe, and are better for the planet.

How It Works

Cooling coatings work well because of smart science and design. The 3U No-Electric Cooling Coating has tiny particles of different sizes. These are put together in a special way. This helps the coating reflect sunlight and send out heat.

-

Nanoparticles near the top reflect many kinds of sunlight.

-

The coating sends out heat in the mid-infrared range. It uses the atmospheric window (8–13 μm) to let heat go into space.

-

This keeps the surface much cooler than the air, even in sunlight, and it does not need electricity.

| Scientific Principle | Mechanism and Explanation |

|---|---|

| Passive Daytime Radiative Cooling (PDRC) | The coating sends heat to space through the atmospheric window. This cools surfaces below the air temperature. |

| High Solar Reflectance (0.3–2.5 μm) | It reflects most sunlight. This stops extra heat from building up. |

| High Long-Wavelength Infrared Emittance | It sends out heat in the 8–13 μm range. This lets heat leave easily. |

| Micro- and Nano-structured Materials | These help scatter light and send out heat for better cooling. |

| Atmospheric Transparency Window | This lets heat pass through the air, so things can cool below the air temperature. |

These coatings use special science to reflect sunlight and send out heat. Tiny structures and new materials help the coating work well. This process is called passive radiative cooling. It works all day and night and does not need power.

Cooling coatings like the 3U No-Electric Cooling Coating use these ideas to help in real life. They make surfaces cooler, lower energy bills, and make places safer and more comfortable. They work well and are a smart pick for new buildings and factories.

Key Benefits

Energy Savings

Next-generation cooling coatings help save a lot of energy. They reflect sunlight and send heat away. This keeps building surfaces cooler. Air conditioning is needed less often. In hot places, cool roofs and coatings can cut cooling energy use by 67% to 87%. For example, in Phoenix, Arizona, buildings with these coatings save up to 6.64 kWh per square meter each year. EnergyPlus tests show these coatings work well in most climates. They are very helpful for buildings with poor insulation. Using less energy means lower bills. Owners get their money back fast, often in one to three years. People pay less for energy and feel more comfortable inside.

Tip: Using a cooling coating can help owners follow strict energy rules and get green building rewards.

Durability

Durability is a big reason people like next-generation cooling coatings. These coatings use strong materials and many layers. They can handle bad weather, UV rays, and big temperature changes. Old coatings might crack or break down fast. New silicone and multilayer coatings last 15 to 25 years if cared for. They do not break down, chalk, or peel, even in very hot or cold places from -60°F to 300°F. Additives like THIXATROL® make the coating stable and easy to put on. This means less fixing is needed over time.

-

Multilayer coatings like WO3/VO2/WO3 work well in high humidity and heat for over 100 days.

-

VO2/HfO2 sandwich films keep working for up to 16 years, even in tough places.

-

Silicone coatings reflect about 90% of UV rays. Standard coatings only reflect 65%.

These features help roofs and walls last longer. They lower repair costs and protect buildings from weather damage.

Sustainability

Sustainability is a main reason cities use next-generation cooling coatings. These coatings help cut greenhouse gas emissions. They do this by lowering the need for air conditioning. Studies show that passive radiative cooling coatings, like reflective paints, lower surface temperatures and energy use. This means less electricity and fewer refrigerants are needed. Both can cause climate change. White and colored coatings with high reflectance also help fight the urban heat island effect. They keep buildings and roads cooler.

| Type of Cooling Coating | Main Benefit |

|---|---|

| Cool Roof Paints | Lower roof temperatures, reduce AC demand |

| Cool Pavement Coatings | Reduce heat in roads and sidewalks |

| High-Performance Facade Coatings | Prevent heat absorption in building walls |

| Solar-Reflective Paints | Keep surfaces cool during peak sunlight |

| Heat-Reflective Roof Coatings | Maximize UV and infrared reflection |

Cooler surfaces mean less heat in cities. This makes people more comfortable and helps building materials last longer. These coatings help meet green building rules and city climate goals. They are a cheap and easy way to make cities more sustainable.

Industry Trends

Innovation Drivers

The industry is moving away from old coatings. New coatings do more than just protect surfaces. Nanocoatings use tiny particles to make thin layers. These layers help reflect sunlight and control heat. Some smart coatings can react to temperature or humidity changes. They can also sense damage or fix themselves. This helps them last longer and work better.

Scientists mix different materials to make new coatings. They use things like CaCO3, TiO2, and SiO2 in polymers. These mixes help coatings reflect more sunlight and send out more heat. For example, SiO2 microspheres can reflect almost all sunlight. They can make inside spaces up to 7°C cooler. Some coatings can lower surface temperatures by over 17°C in tests. There are also coatings that clean themselves. Some are thin and light for cars and electronics. These new features make coatings much better.

Smart coatings have changed cooling coatings a lot. They are now high-performance and save energy.

Adoption Growth

More companies are starting to use next-generation cooling coatings. Data centers use them the most. They need to keep computers cool and save energy. Other industries like electronics, medicine, cars, and food are using them too. These companies want to spend less on energy and follow new rules.

| Sector | Adoption Speed / Market Share | Driving Factors |

|---|---|---|

| Data Centers | Fastest adoption, largest market share | High computing demand, energy efficiency, incentives |

| Electronics Manufacturing | Rapid adoption | Automation, urban growth, environmental awareness |

| Pharmaceuticals | Rapid adoption | Manufacturing growth, sustainability goals |

| Automotive | Rapid adoption | Industrialization, energy efficiency |

| Food & Beverage | Rapid adoption | Sustainability, emissions regulations |

The market for these coatings is growing fast. It could grow by 12% each year from 2025 to 2033. The market might be worth $8 billion by 2033. Builders use these coatings in many places. They use them in buildings, factories, and roads. Products like the 3U No-Electric Cooling Coating are setting new standards. This helps more people start using these coatings.

Applications

Buildings

Builders have found that next-generation cooling coatings work well. They use them on homes and school buildings. These coatings go on stucco, plaster, and paint. The coatings reflect sunlight and make surfaces cooler by 10–15°C. This helps rooms stay cooler inside. People do not need air conditioning as much. It makes hot days more comfortable. Owners also save money on energy bills. The coatings protect walls from weather and UV rays. This helps buildings last longer.

-

Common building applications:

-

Residential homes

-

University and school buildings

-

Offices and commercial spaces

-

Note: Cooling coatings can make rooms up to 5.9°F cooler, even if there is no air conditioning.

Industrial Uses

Many factories use cooling coatings to keep things safe. Chemical plants and food storage places use them on equipment. The coatings protect machines from heat, fire, and rust. This lowers the chance of accidents. Machines last longer and work better. In food factories, coatings help keep things clean. They stop germs and are easy to wash. Big industries like aerospace and power plants use these coatings too. They help parts last longer and need less fixing. This saves money and time.

| Industry Sector | Application Examples | Key Benefits |

|---|---|---|

| Petrochemical | Pipelines, heat exchangers | Less fouling, better flow, less downtime |

| Aerospace | Fuel systems, engine parts | Fewer blockages, longer equipment life |

| Power Generation | Boilers, turbines | Less corrosion, higher efficiency |

Infrastructure

Cooling coatings help protect bridges, roads, and concrete. They reflect sunlight and make surfaces up to 15°C cooler. This stops roads and bridges from cracking and getting ruts. The coatings do not make the materials weaker. They help roads and bridges last longer. Cities spend less money fixing them. Cooler surfaces also make cities safer and nicer for people.

Tip: Putting cooling coatings on roads and bridges can help cities stay cooler and safer for everyone.

Overcoming Challenges

Cost

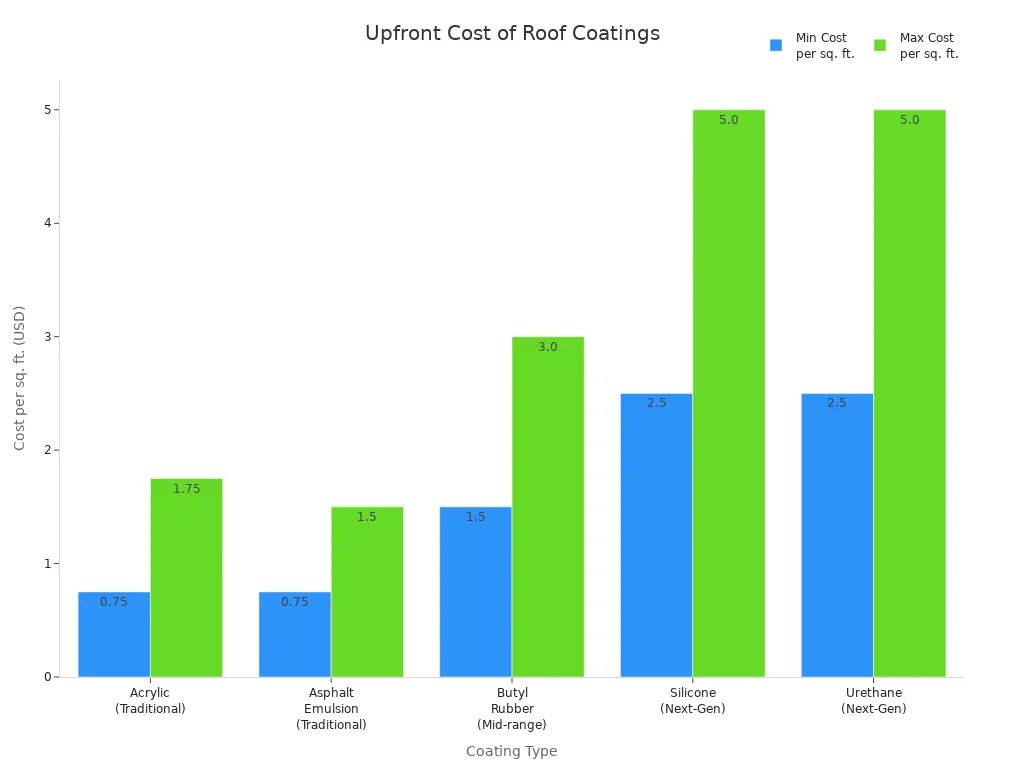

Builders sometimes worry about the price of new coatings. Next-generation coatings like silicone and urethane cost more than old types. Acrylic and asphalt coatings are cheaper. But these new coatings still cost less than replacing a whole roof or using metal roofing. The table below shows how much each type costs:

| Coating Type | Typical Upfront Cost (per sq. ft.) | Notes on Performance and Benefits |

|---|---|---|

| Acrylic (Traditional) | $0.75 – $1.75 | Cost-effective, good durability and reflectivity |

| Asphalt Emulsion | $0.75 – $1.50 | Affordable, easy to apply |

| Butyl Rubber (Mid-range) | $1.50 – $3.00 | Higher durability, more expensive |

| Silicone (Next-Generation) | $2.50 – $5.00 | Premium, excellent UV and water resistance |

| Urethane (Next-Generation) | $2.50 – $5.00 | Highly durable, excellent adhesion and impact resistance |

Builders say the higher price is worth it. These coatings help save money on energy and repairs. They also make roofs last longer. Over time, the money saved can cover the first cost. Many owners get their money back in just a few years.

Installation

Some workers do not want to try new coatings. They trust the old ways and worry about how well new coatings will work. Old methods use more labor, but coatings can change this. Some people do not like that many cool coatings are white. Some building rules do not allow certain roof colors.

Researchers and companies are fixing these problems:

-

They make colored coatings that still reflect sunlight.

-

They design coatings that go on like paint or wallpaper.

-

They share clear data about how well coatings work, like solar reflectance index, so people can choose wisely.

Note: New coatings can go on many shapes and surfaces. Some come in big rolls for fast work.

Longevity

Builders and owners care about how long coatings last. Advanced coatings have strong bonds and special structures. This helps them stand up to heat, chemicals, and weather. For example, silicone resins with siloxane bonds handle heat and light better than old coatings. These coatings keep their color and stick well for a long time.

Thermo-reflective and ceramic-based coatings also stick well and stay strong. They keep out water and stop rust, even in hard places. Scientists keep working to make coatings last longer. They study how coatings age and how to fix or add more when needed.

Tip: Using primers and extra layers helps coatings last longer on rough surfaces like mudbrick.

Future Outlook

Emerging Tech

Surface cooling is getting better with new materials and smart features. Scientists are making coatings that do more than just cool things down. Some of the best new technologies are:

-

Temperature Indicating Coatings: These use metal and ceramic nanomaterials to show temperature changes right away. Aerospace and electronics companies use them for safety and to work better.

-

Solar Coating Technology: This puts special particles in paint. These surfaces can collect solar energy. This helps in places where solar panels cannot fit.

-

Heat-Resistant and Corrosion-Resistant Coatings: Ceramics and silicones protect against heat, UV rays, and rust. These coatings help equipment last longer in marine, car, and renewable energy fields.

-

Porous Radiative Cooling Coatings: Materials like silica aerogel and titanium dioxide reflect sunlight and send out heat well. They can cool surfaces up to 7.8°C below air temperature at noon.

-

Polyvinylidene Fluoride and Hydromagnesite-Based Coatings: These coatings cool well and help control heat in batteries and wearable devices. They also save energy and lower carbon emissions.

Note: Many new coatings use photonic structures and nanoparticle-embedded polymers. These features give them special cooling powers and make them useful for many jobs.

Market Growth

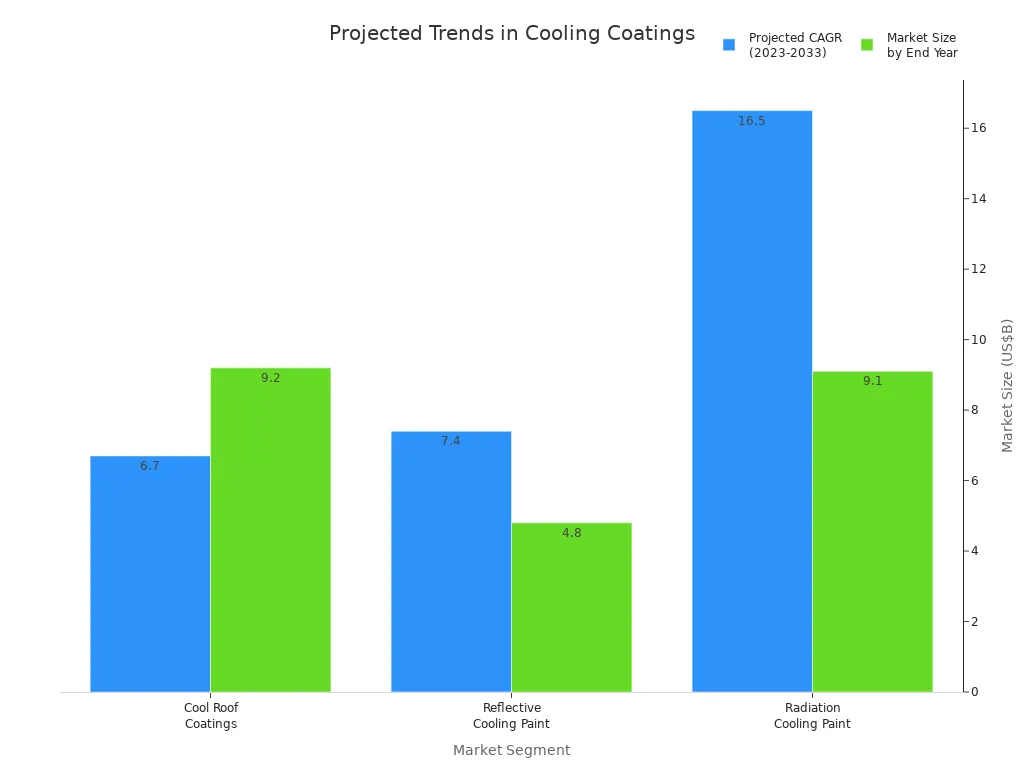

The market for advanced surface cooling is growing fast. Companies and governments want to save energy and follow new climate rules. The table below shows important trends for the next ten years:

| Market Segment | Projected CAGR | Market Size by End Year | Key Drivers and Trends |

|---|---|---|---|

| Cool Roof Coatings | 6.7% (2023-2030) | US$9.2 billion by 2030 | Higher energy costs, new rules, climate awareness, better technology |

| Reflective Cooling Paint | 7.4% (2026-2033) | US$4.8 billion by 2033 | Need for energy savings, government rules, more people know about it, used in cars and buildings |

| Radiation Cooling Paint | 16.5% (2026-2033) | US$9.1 billion by 2033 | AI and automation, new rules, more cities, electric cars, aerospace |

North America is the biggest market, but Asia Pacific is growing fastest. Builders see new chances in electric cars, aerospace, and wearable electronics. Companies spend money on research and work together to make better products. Builders who want to stay ahead should watch these trends and think about using new surface cooling technologies when they come out.

Builders pick next-generation cooling coating to save energy. These coatings last a long time and help the planet. New ideas like the 3U No-Electric Cooling Coating change how buildings stay cool. These coatings lower costs and help with green goals. Many industries now see why advanced coatings are good. Readers can look at different choices to help make buildings cooler and greener.

FAQ

What surfaces can next-generation cooling coatings cover?

Builders can put these coatings on metal, concrete, and asphalt. They also work on many kinds of plastic. The 3U No-Electric Cooling Coating goes on roofs and walls. It can be used on pipelines, silos, and bridges too. It fits both flat and curved shapes.

How long does a cooling coating last?

Most next-generation cooling coatings last 15 to 25 years. This is if you take care of them the right way. The 3U No-Electric Cooling Coating stands up to weather and UV rays. It also resists chemicals. This helps the surface last longer.

Do cooling coatings require special maintenance?

You only need to clean the coating with water and mild soap. This keeps it working well. Check the coating every year to find any damage early. Most coatings do not need lots of repairs or new coats.

Can cooling coatings help meet green building standards?

Yes, they can. Cooling coatings help lower energy use and cut down emissions. Builders use them to get LEED certification. They also help meet local energy rules. These coatings help with green building goals.

How quickly can owners see a return on investment?

Most owners get their money back in one to three years. Saving energy and spending less on repairs makes these coatings a smart choice for many projects.