How to avoid fog in helmet visor?

For professional riders, a foggy visor isn’t just an inconvenience; it is a critical performance barrier. When you are competing at high speeds, any compromise in optical clarity directly impacts safety and precision.

To avoid fog in a helmet visor at a professional level, the industry is moving toward super-hydrophilic nano-coatings. Unlike temporary sprays or mechanical inserts, these coatings transform the visor surface to spread moisture into a clear, invisible film, providing permanent high-definition vision without extra layers.

I have spent years working with premium gear, and I know that while standard solutions serve the general market well, they often hit a "performance ceiling" in extreme racing conditions. Let’s explore why high-end manufacturers are now looking toward material science to deliver the next generation of professional optics.

Why are high-end manufacturers seeking alternatives to traditional anti-fog?

Traditional methods like Pinlock or basic hydrophilic resins remain the standard for the mass market because they are cost-effective and reliable for daily commuting. However, for the professional racing segment, these solutions can introduce subtle optical trade-offs that elite athletes want to eliminate.

While effective for general use, mechanical inserts can limit the vertical field of view or cause "ghosting" from track lights during night races. For premium brands, the goal is to provide a "native" fog-free experience that maintains the pure optical integrity of a single-pane polycarbonate lens.

The Limitations of Add-on Solutions in Professional Racing

In my experience with racing teams, every millimeter of vision counts. When a rider is in a full tuck, the top edge of a traditional anti-fog insert can sit right in their line of sight. This is why many professional-grade helmets are shifting focus. We aren’t saying traditional methods don’t work—they are excellent for millions of riders—but they are a "mechanical" fix for what is essentially a "material" problem.

Another challenge for premium OEMs is the "saturation point" of standard hydrophilic resins. Many factory-applied coatings act like a sponge. They absorb moisture until they can’t hold any more, at which point they can become "milky" or distorted. For a professional brand, this degradation is a risk to their high-performance promise. They need a surface that doesn’t just store water but manages it dynamically through super-hydrophilic action.

Anti-Fog Technology Evolution for Different Market Segments

| Feature | Standard (Sprays/Dips) | Mid-Range (Inserts) | Premium (Nano-Coatings) |

|---|---|---|---|

| Primary User | Occasional Riders | Daily Commuters | Professional Racers/OEMs |

| Optical Path | Single Layer | Double Layer | Single Layer (Native) |

| Maintenance | High (Re-apply) | Low (Replace seal) | Minimal (Permanent) |

| Field of View | Full | Limited by border | Full |

| Durability | Days | 1-2 Seasons | Lifecycle of Visor |

I believe we are seeing a clear split in the market. The mass market will continue to rely on the proven success of inserts because they are affordable and easy to understand. But for the "elite" tier, the focus has shifted to the molecular structure of the visor itself. If you can make the polycarbonate naturally repel fog through nano-engineering, you remove the need for the customer to manage extra parts or worry about seal failures.

How do super-hydrophilic nano-coatings solve the durability problem?

Historically, the trade-off for high-clarity hydrophilic coatings was their soft surface, which scratched easily during cleaning. For a high-end product, a visor that scratches after one wipe is a failure, regardless of how well it stays fog-free.

Modern super-hydrophilic nano-coatings solve this by using a cross-linked silica matrix. This chemical bond creates a surface that is both "water-loving" (preventing fog) and physically hard (resisting abrasion). This allows manufacturers to offer a permanent anti-fog solution that is tough enough for the rigors of professional use.

Balancing Surface Energy and Mechanical Hardness

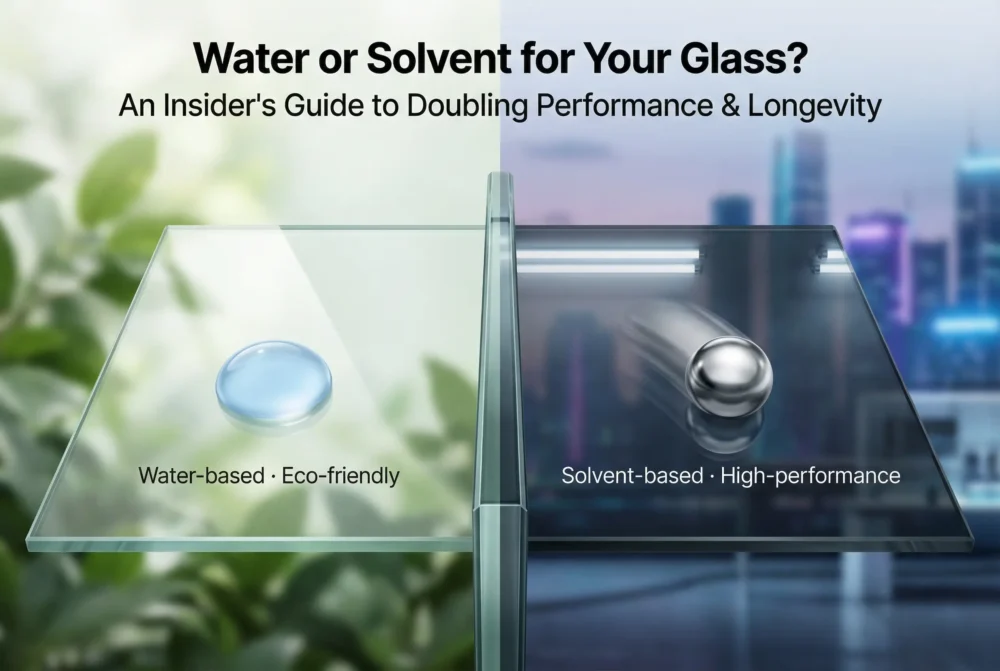

When I talk to R&D departments, the discussion is always about "contact angles." A super-hydrophilic surface has a contact angle of nearly zero. This means water cannot form a bead; it must lay flat. The technical challenge was making that "flat water" layer work on a surface that won’t scratch when a rider wipes away track grime with a glove.

By using nano-particles, we can now "anchor" the anti-fog properties deep into the polymer. This isn’t just a layer sitting on top; it becomes part of the visor’s skin. I have seen tests where these coatings maintain their fog-free properties even after hundreds of cleaning cycles. For a B2B manufacturer,