🤖 Are There Robotic Solar Panel Cleaners?

My solar farm, a massive 5MW array, faced a crippling problem. Severe dust storms in our area routinely cut the output by 25% in just months. Hiring manual cleaning crews was not only prohibitively expensive and risky, but they couldn’t keep up with the frequency needed. Then I discovered robotic cleaners—a crucial technological upgrade that completely redefined our operational efficiency.

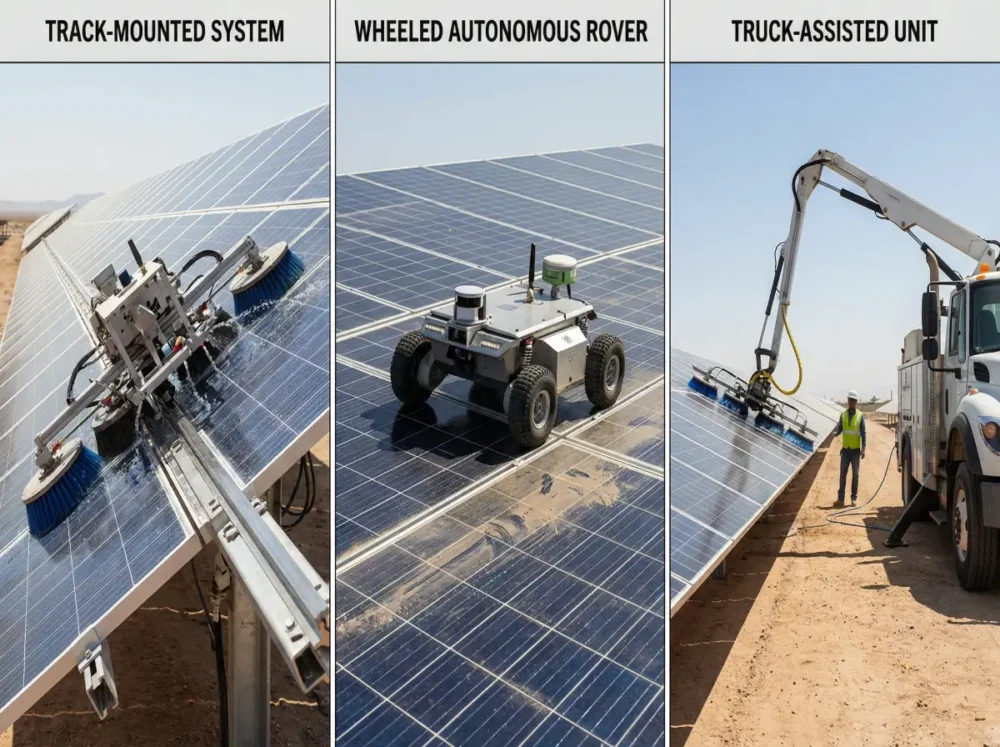

Yes, robotic solar panel cleaners exist and are the standard in large-scale PV farms globally. They automate cleaning to slash labor costs by up to 70%, boost annualized energy yield by 15–30%, and operate reliably unmanned. Models range from track-mounted sweepers ideal for fixed tilts to wheeled bots that handle uneven terrain, primarily using dry brushing or efficient water jets.

If you are managing utility-scale solar assets and tired of spiraling manual O&M costs, stick around. As a farm manager who made the switch, I’ll break down how these robots work, compare their costs to outdated methods, and share my journey to achieving consistent, high-yield performance.

What Are Robotic Solar Panel Cleaners?

My team’s first $15,000 cleaning bill for just one sector of the 5MW array was a wake-up call. We worried about inconsistent cleaning quality and the associated safety risks for workers on elevated structures. Robots fixed those issues overnight.

Robotic cleaners are purpose-built automated devices designed specifically for utility-scale PV arrays. They include permanent track-based sweepers, large wheeled rovers, and specialized drone-assisted units. They systematically remove dust, pollen, and bird droppings without human intervention on the panel surface.

How Robots Clean Solar Panels

Robots use advanced sensors (Lidar, GPS, or edge detection) to navigate the array structure precisely. They primarily employ dry brushing with soft micro-fiber rollers, air blasts, or, for stubborn buildup, low-pressure water. Most models are self-charging, running on onboard solar power, eliminating external energy demands.

Last year, after installation, our basic fleet of wheeled models covered 1MW in days, not the weeks manual crews required.

Key Features of Top Robotic Models

| Feature | Benefit | Example Application |

|---|---|---|

| Autonomous Navigation | Eliminates manual steering; utilizes GPS/sensor mapping | Fixed-tilt arrays requiring precise, pre-programmed paths |

| Dry Cleaning Mode | Saves $90\%$ water vs. traditional wet methods; zero water risk | Desert/Arid Zones where water scarcity is critical |

| Water Jet Option | Handles sticky grime (e.g., bird droppings, pollen residue) | Areas with high humidity or biological contaminants |

| Battery/Solar Powered | Enables 24/7 operation in remote sites, often cleaning at night | Remote Locations with limited access to power infrastructure |

| Initial Investment | $\$5,000 – \$50,000$ per unit (Varies by scale and type) | Payback in 1–2 years through sustained yield increases |

These automated systems provide a rapid return on investment. In highly dusty environments, they are scheduled to clean weekly. Our 5MW array runs bi-weekly, maintaining a consistent 18% higher output compared to manual periods.

The benefits far outweigh the initial costs for farms over 1MW. While initial setup is easier on flat arrays, the technology now adapts to tilts up to 30 degrees and tracker systems.

How Do Robotic Cleaners Compare to Manual Methods?

Before the switch, we paid \$1,760 per MW for manual cleaning, only to see labor shortages double that cost during peak seasons. Robots have slashed that recurring expenditure to minimal operational fees.

Robotic methods are fundamentally superior in scale, speed, and long-term cost-efficiency for large-scale stations. Manual labor is unsuitable for utility-scale efficiency requirements.

Cost Breakdown: Manual vs. Robotic (Per MW/Year)

Manual cleaning for a 1MW sector requires approximately 22 worker-days (at $\$80$/day), costing roughly $\$1,760$ per session. If we clean 3 times a month (standard for arid zones), the Annual Manual Cost is roughly $\$63,000$ per MW.

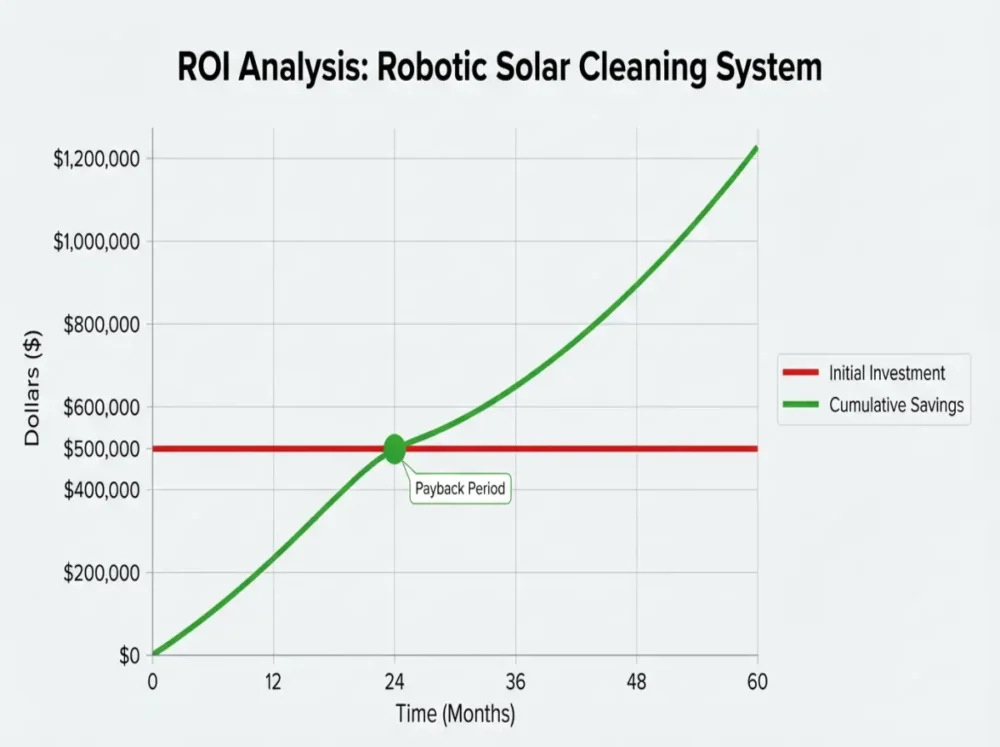

Robotic systems for a 10MW array might cost $\$100,000-\$500,000$ upfront. Amortized over 10 years, the annual capital cost plus minimal operational expenses result in significantly lower overall cost.

| Method | Cost per MW/Year | Water Use (per MW/clean) | Efficiency (MW/day) | Labor Needed |

|---|---|---|---|---|

| Manual Dry Wipe | $\approx \$63,000$ | None | $0.05$ | High (22 days) |

| Hose Washing | $\approx \$130,000$ | $10$ tons | $0.1$ | Medium (2-4 people) |

| Robotic Sweeper | $\approx \$10,000 – \$20,000$ | $0-2$ tons (dry mode) | $1-2$ | None (Remote Monitoring) |

| Mobile Cleaner (Truck) | $\approx \$50,000$ | $5$ tons | $0.5-1$ | Low (1 driver) |

Industry data confirms that robotic solutions yield an average 20% ROI over 5 years due to consistent energy production. While manual performance drops in wet climates, robotics shine in the high-frequency demands of dry, dusty regions.

Our neighboring farm switched after a major dust storm event. Their monitored yield immediately jumped 22% with zero water waste.

Environmental and Safety Edges

Manual cleaning introduces risks of worker slips, falls, and potential chemical runoff/spills. Robots eliminate the need for personnel on the array surfaces entirely. Crucially, dry cleaning bots dramatically cut water use—a paramount concern for farm locations in arid zones.

In areas like the Gobi Desert, robots are essential, handling high-abrasion sand and dust without damaging the panels or leaving residue.

Are Robotic Cleaners Worth the Investment for Large Farms?

When a major storm buried our 5MW panels in grit, manual recovery took weeks and cost over $\$20,000$. A dedicated robotic fleet would have mitigated the buildup immediately and prevented days of lost generation for a fraction of that cost.

For stations over 1MW, the answer is unequivocally yes—payback is typically achieved within 18-24 months.

Factors to Consider for Your Utility-Scale Setup

Operational needs vary by geography. Dusty deserts necessitate weekly runs; mild, rainy coasts may only require quarterly cleaning.

| Factor | Robotic Fit (Ideal) | Manual Alternative (Suboptimal) |

|---|---|---|

| Array Size | $>1 \text{MW}$ (Essential at $5 \text{MW}+$) | $<1 \text{MW}$ (Small commercial/residential) |

| Terrain/Structure | Flat/tracked systems, consistent panel rows | Highly sloped or irregularly configured roofs |

| Budget | High initial CAPEX ($\$10 \text{K}+$ per MW) | High recurring OPEX ($\$60 \text{K}+$ per MW/year) |

| Water Access | Low (allows use of dry bots) | High (requires hose/truck washing) |

| Yield Loss Risk | High dust areas/High soiling rates | Mild climates/Low soiling rates |

I calculated that the sustained 15% yield gain on our 5MW farm covered the cost of our robotic fleet purchase well within two years. The global solar cleaning market is projected to hit $\$1$ Billion by 2027.

Vendors like Ecoppia offer O&M service models or leases—sometimes priced as low as $\$0.01/\text{kWh}$ cleaned. This eliminates upfront CAPEX risk for farm owners.

Real-World Case: My 5MW Switch

Before integrating the robotic fleet, our production losses peaked at 28% during high-soiling months. Post-install, we maintain a steady $98\%$ peak performance availability. The only glitch? A minor remote-app sensor error, which we fixed instantly from the control room.

Robots scale perfectly for large farms and integrate directly with SCADA and monitoring systems for auto-triggers based on real-time dust level data or weather events.

What About Advanced Robotic Options?

Early generation bots were crude; new models use soft rollers, predictive AI pathing, and gentle suction to prevent micro-scratches on expensive panel coatings.

While drones can inspect array borders, the heavy-duty, consistent cleaning power of ground-based robotic fleets remains the industry standard.

Emerging Trends in 2025

Artificial Intelligence is now used to predict soiling rates and schedule cleaning based on hyper-local weather data, optimizing cleaning cycles (preventative maintenance). We are also seeing hybrid bots that combine sweeping with UV sterilization to combat biological contaminants.

We expect system costs to drop by another 15% yearly due to competition. Our recent upgrade involved adding a full sensor package to our existing fleet for just $\$2,000$ per unit, significantly improving navigation.

In massive deployment zones, 100MW farms often rely on 500+ bots running concurrently, achieving near-zero soiling downtime.

Conclusion

Robotic solar cleaners are a non-negotiable component of modern PV maintenance—saving up to 70% in labor while reliably hiking yields by 20%. For utility-scale arrays and farms over 1MW, they are essential infrastructure, not optional O&M tools.